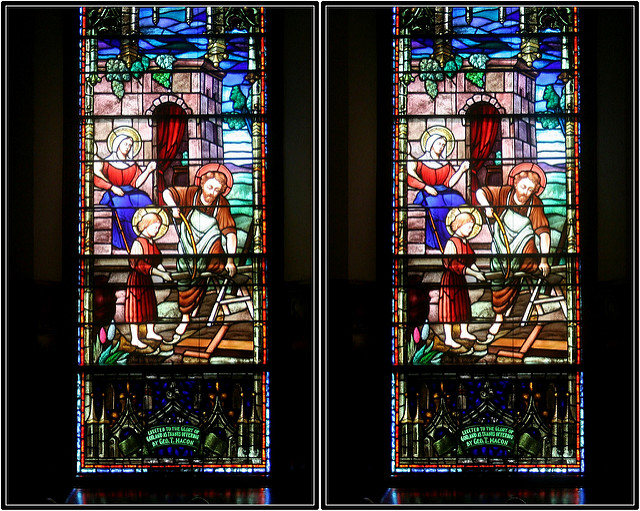

Stained glass that is built to last.

The process of stained glass fabrication has been going on for centuries, in much the same fashion as it originated. The process is still the same in the sense of the end product being beautiful stained glass windows. And in our case, the process is still the same in terms of hand building each one of our custom windows, so we can offer the utmost in stained glass quality.

However, there have been some changes in methods and materials that help to assure high-quality stained glass that is built to last throughout many generations. Our stained glass windows and panels might wind up becoming family heirlooms. They can be uninstalled and moved to a new home, they are that durable.

So although the end product’s beauty remains the same as with stained glass of old, the process we use and the materials we use have evolved over time.

Even though we make custom designed, hand built stained glass, the computer has become a lynchpin of stained glass quality for us. We use CAD technology to create our final patterns, ensuring a perfect fit in your windows or doors. After all, if a stained glass panel is even one quarter inch too big or small, it will not fit into its allotted window frame, which would be a disaster.

The CAD and other computer software also allow us to show the client an exact rendering of their design, so they can see what it will look like before it’s even built, before the glass and other materials are even ordered.

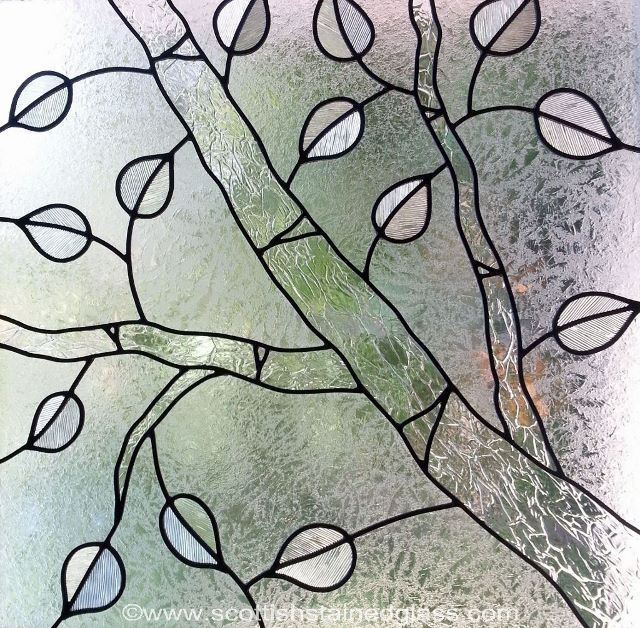

Our artisans still hand cut and hand assemble and hand polish each stained glass window, following our computer generated, exact down to the millimeter pattern. But some of the materials we are now using are greatly improved over what stained glass makers in the eighteenth century had to work with. There have been many improvements to the production of glass itself over the centuries, and our glass is sourced from the top glass makers around the globe.

We also use special dark leads to join the pieces of glass together, hidden solder joints, extremely precise soldering temperatures, a unique polishing process that we developed ourselves. And when it comes to installation, we have also developed our own installation techniques that ensure a protected stained glass panel, and a tight, weatherproof seal.

There is a lot of mass produced stained glass on the market. We don’t want to disparage it, but we are absolutely confident that when you see our custom stained glass’s quality, the difference will leap out at you immediately. And don’t be surprised if the prices is more affordable than you’d think!

For stained glass built to last, that cannot be beaten anywhere, we hope you will consider Custom Stained Glass. We would love to work with you.